Application of IQF freezer equipment

Application of IQF freezer equipment China's development of frozen food late start, the annual growth rate of its development More than 25%. Even now our annual per capacity consumption is only one-tenth of the developed countries. So great development space. With the development of frozen food industry and its industrial production, quick-freezing machine has become an irreplaceable necessary equipment. At present, China 28 kinds of food market access system specified in the frozen foods, especially cooked food must IQF device quality assurance, export commodity inspection has also been requested. This article explores why irreplaceable in the food industry, freezers, freezer and traditional frozen bank What is the difference, how to choose the right freezer, freezer direction of how to meet the further development of a number of different food and different processing needs, quick-freezing machine and how energy-efficient, intelligent frozen frozen manufacturers the opportunity to benefit. First, the impact factors of frozen food When the food freezing speed per hour 5-50 mm thickness, to ensure the food during freezing ice crystal size of the number generated substantially constant, relatively small grains,So as to achieve the preservation of reversibility。 It contains two moisture foods, a free water that ice crystal formation stage 0 to 5 degrees A colloidal bound water molecule that is attached to the surface of the food, when frozen goods -18 degrees, crystallinity of 95% or more. In addition, low-temperature environment after the ice crystal inhibition of microbial activity food storage and reproduction, the purpose of long-term storage and preservation (fruit and vegetable respiration inhibiting heat). Factors frozen food can be divided into: 1.Coolant temperature: food freezing speed and the temperature difference between the freezing point of the cooling medium Proportional to Δt. The lower the coolant temperature, the faster freeze. 2.Frozen impact on the wind: the wind surface area, wind speed, cold air circulation rate affect the freezing speed: tests show that green beans on-30 degrees coolant required 120 minutes at 0 when the wind speed, when 4.5m / s wind speed in just 10 minutes. 3.Latent heat and enthalpy difference of influence:1kg of water from 80 degrees to 0 degrees 80 kcal cold needed, from 0 degree 0 degree water into ice 80kcal also requires refrigeration. Visible latent heat of crystallization requires more cooling capacity. Similarly when the enthalpy difference is large, such as higher stock temperatures, not only requires a large amount of cooling also takes a long time to freeze. 4.Effects of food components: a high thermal conductivity food faster than low thermal conductivity rate freeze food, if food is not only thermally conductive surface deposited plastic film slow and hinder the wind. Thermal conductivity of water 0.604w / mk, fat thermal conductivity of 0.15, thermal conductivity of 0.028 plastic film, the thermal conductivity of air is 0.066. 5.The thickness of the impact of food: food is directly proportional to the square of the thickness of time and frozen. The thicker the food, Frozen longer time. Second, the transition from the freezer of frozen bank Seen from the frozen food factors: Since the frozen bank once more open purchase amount, a relatively high temperature of food, the temperature rise of the cooling medium volatility, reducedΔt; and freezer to keep the indoor temperature is almost constant. Since the frozen food compartment placed in a static, non-uniformity of the generated wind, the wind speed decreases even static way hinder the crystallization speed hair Frozen i.e. the central portion of the wind; each monomer within the wind tunnel surface area Freezer large and remain uniform, but also because of changes in wind speed up freezing. Since entering the frozen food bank while achieving latent heat, sudden need to greatly improve the cold face of the crystallization process, resulting in crystallization temperature rise and extension of time. And continuous operation of the freezer so that the already limited capacity Frozen relatively few have reached the latent heat section, an amount which is sufficient to complete the rapid cooling crystallization process at a stable temperature, speed. Thus, the pursuit of fast food reversibility of the crystallization process so as to achieve the effect of food preservation, quick-freezing machine is essential. Third, the air as the cooling medium freezer classification and characteristics ①IQF fluidized machine: the hair style. Frozen freeze single drift forward in the process For fruits and vegetables, granulated food. Capacity 100-3000 kg/h ②Surface fluidized IQF machine, frozen goods expanded species, saving energy. The creative combination of frozen fluidized tunnel. Excellent freeze effect. ③Fluidizing monomer pre-cooling freezer. Fluidized-style additional pre-cooling function on the basis of IQF machine. 4) Propulsive Freezer: ①No power transfer, frozen stepping rail by static friction Pro gravity point session easy operation, to avoid running cold. ②Apply to prepared foods, ice cream, chunks of food, bags of frozen boxed food. Fourth, on the freezer energy-saving, reliable, reasonable and intelligent Food freezing speed and temperature difference Proportional to Δt. The pursuit of low temperature inside the freezer to crystallize fast food, set the temperature at -35 degrees, on the one hand consider the rapid freeze, on the one hand consider saving energy. Therefore, the more food into the cargo temperature is near freezing, the frozen food accelerated. The left pre-cooling before crystallization of the completion of a higher temperature, so as to achieve energy saving and high-quality frozen object. In addition, the cargo temperature near freezing or reducing food consumption of key stakeholders. Cold consumers avoid freezer to avoid further consumption of cold splicing gap envelope of the insulation board. In Freezer envelope insulation panels take the form of a polyurethane foam as a whole, all of the library are double-sided board connector patchwork special sealant filling accompanied by secondary expansion, avoiding splicing gap insulation board run cold. Freezer the various requirements for volume and velocity is different, its energy-saving methods are different. Tunnel IQF machine mesh belt, on the basis of design to ensure that the cooling air Flow regulating grille bar assembly, greatly Frozen improve surface wind speed. While also improving the wind Frozen surface area, improve circulation rate of the wind. In addition, a symmetric adjustable direction means Flow regulating grille bar assembly, can be Control of cold air from the mouth into the ship ran cold. Fan motor to reduce operating power, thereby reducing the blower motor cooling consumption (pressure decrease, reducing the fan speed) to increase efficiency. To reduce mechanical transmission, a method of cooling consumption belt, this will be taken to maintain the mechanical transmission and conveyor belt system running at a low temperature, the insulation material inlet and outlet measures to utilize the quick freezing compartment from the cold air lingering purpose of saving consumption of cold. |

|||

①Flat belt Freezer: adapted meat, prepared food, aquaculture, food, ice cream and the like. Basic universal freezer. In its production 100 kg/h-2000 kg/h

②Multi-functional vibrating belt freezer: in the plane of belt IQF machine on the basis of an additional general-purpose dynamic apparatus. In addition to having universal flat belt IQF machine characteristics, but also applicable to a particulate frozen food monomers.

③Pre-cooling tunnel freezer: Creative Pre-cooled, frozen into one, saving energy. Especially for high temperature into the goods, fast cooling cooked food.

④Impact belt tunnel freezer: Suitable for small footprint, long time frozen products.

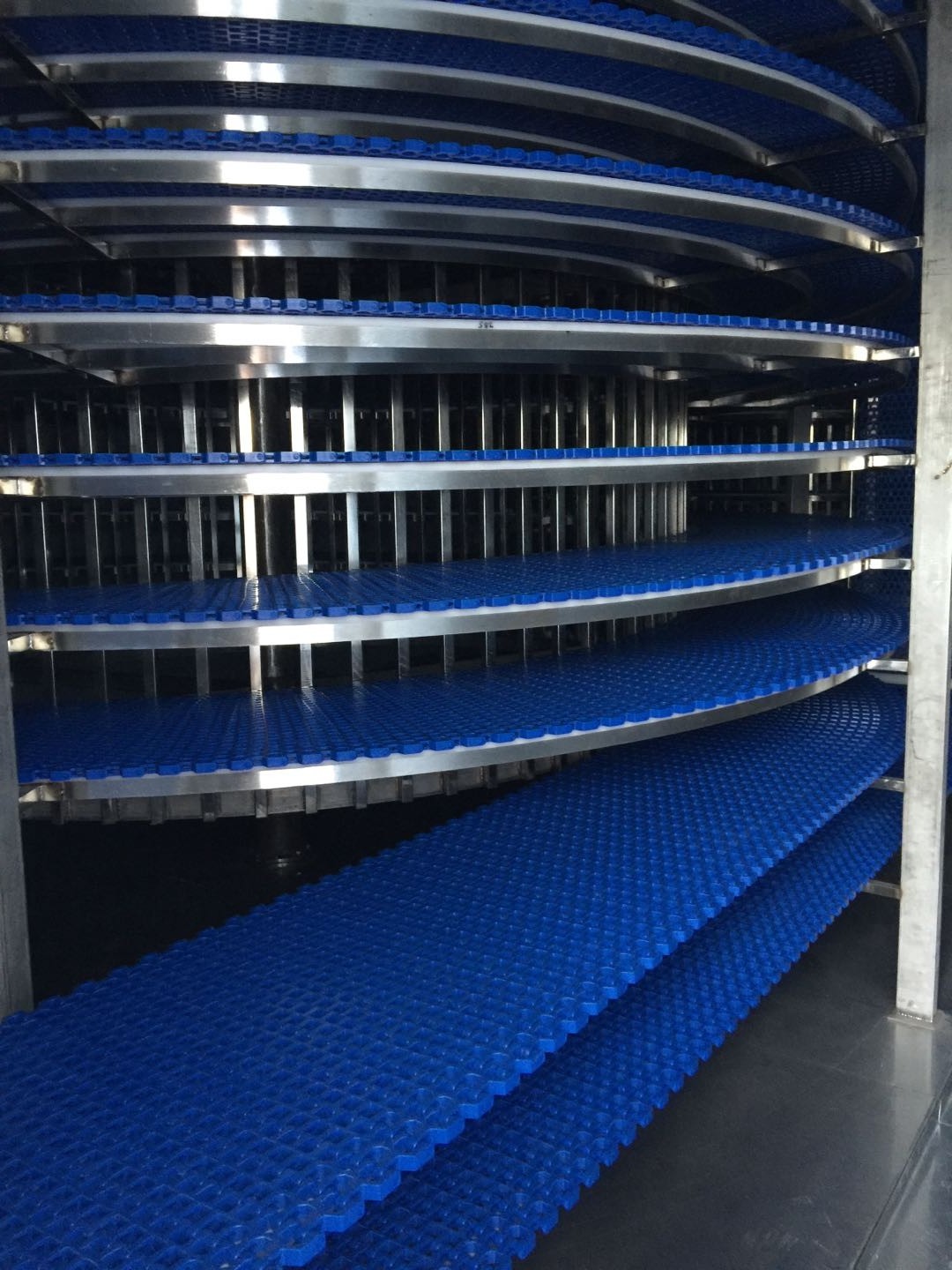

①Single spiral freezer: adapted meat, prepared food, aquaculture, food, ice cream and the like. Small footprint, high efficiency. Expected out low prices or high-low, Capacity 500-1500 kg/h.

②Double spiral freezer: adapted meat, prepared food, aquaculture, food, ice cream and other frozen long time or large frozen food production. Expected out the process plant by a user request to provide various directions; expected out preferential low. Capacity 1000-3000 kg / h.